Schneider Electric España S.A. kombiniert Funktion und Design mit Werkzeugen der Friedrich GmbH

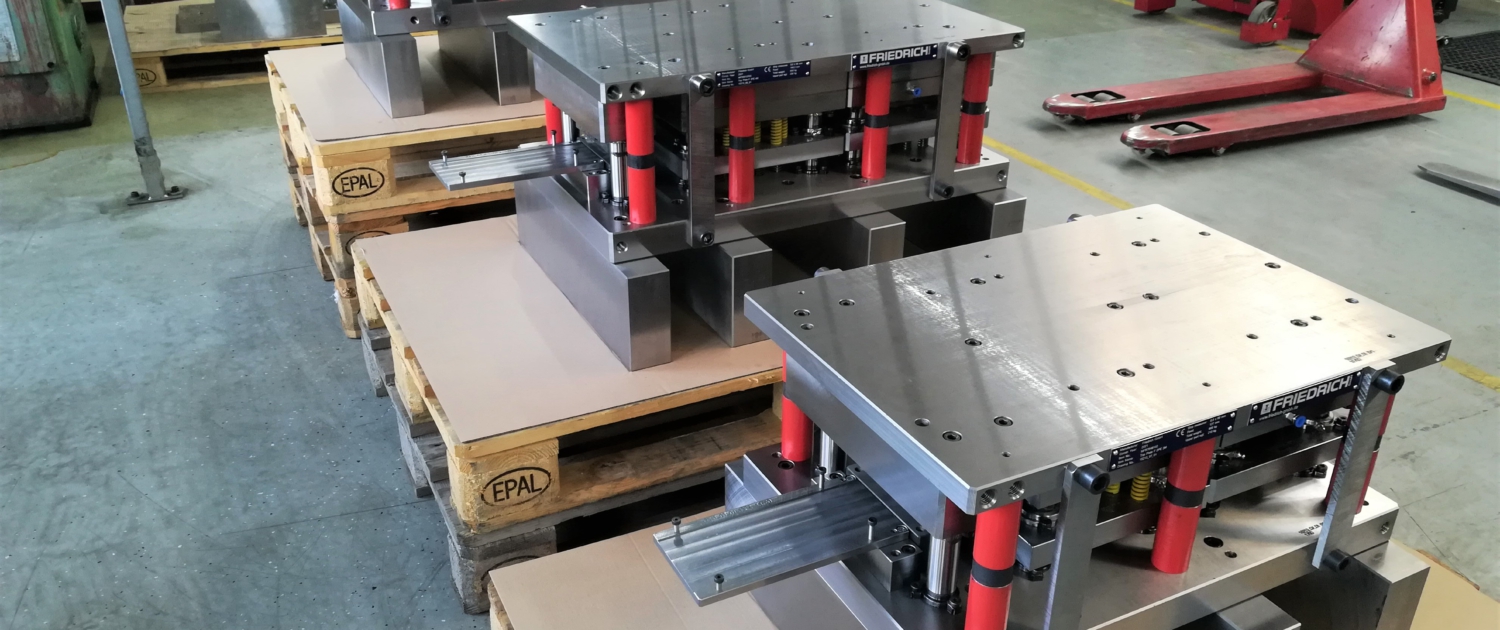

Die Schneider Electric España S.A. (Schneider Electric) suchte einen Partner für Werkzeuge zur Herstellung von tiefgezogenen Sichtteilen aus Aluminium und ist im Erzgebirge fündig geworden. In dem gemeinsamen Projekt mit der Friedrich GmbH (Friedrich) entstanden drei Folgeverbundwerkzeuge zur Produktion von Lichtschalterrahmen aus Aluminium.

Die Herausforderung für die Werkzeugprofis bei Friedrich in dem jetzt abgeschlossenen neuen Projekt mit Schneider Electric bestand darin, dass es sich bei den zu fertigenden Teilen um eine komplexe Freiform handelte. Die Maßhaltigkeit der umgeformten Teile und eine perfekte Oberfläche waren bei den erstklassigen Sichtteilen zwingend erforderlich. Um die individuellen Kundenanforderungen exakt umzusetzen, simulierten die Mitarbeiter bei Friedrich die Umformung. So erreichten sie schließlich nach mehrfachen Optimierungsschleifen die akkurate Form, so dass mit den Transferwerkzeugen die Rahmen qualitätsgerecht hergestellt werden können. Das Stanzen findet bei einem Partner von Schneider Electric, Meconet Oy, in Vantaa/Finnland statt und die finale Montage der Schalterbaugruppen erfolgt bei Schneider Electric in Puente la Reina/Spanien.

English version:

Schneider Electric España S.A. combines function and design with tools from Friedrich GmbH

Schneider Electric España, S.A. (Schneider Electric) was looking for a partner for tools to produce deep-drawn trim parts made of aluminum and found what it was looking for in the Ore Mountains. The joint project with Friedrich GmbH (Friedrich) resulted in three progressive dies to produce aluminum light switch frames.

Schneider Electric has set itself the goal of promoting digital transformation. The use of process and energy technologies, networked products, control components and software enable integrated management for private and commercial buildings. Combining function and design throughout the entire product life cycle is one of the core premises of the globally active company. Already in 2018/2019, the German subsidiary Schneider Electric GmbH c/o Merten benefited from the technological expertise of Friedrich GmbH from the region Ore Mountains in a joint project. High-quality tools were also designed, constructed, built, and tested in cooperation, resulting in Friedrich being listed as one of the few qualified suppliers in this field with the internationally operating group.

The challenge for the tool manufacturers at Friedrich in the new project with Schneider Electric, which has now been completed, was that the parts to be manufactured were a complex freeform. Dimensional accuracy of the formed parts and a perfect surface were imperative for the first-class trim parts. To precisely implement the individual customer requirements, the employees at Friedrich simulated the forming process. In this way, after multiple optimization loops, they finally achieved the accurate shape so that the frames could be produced with the transfer tools in line with quality requirements. The stamping happens at Meconet Oy in Vantaa/Finland and the final assembly of the frames takes place at Schneider Electric in Puente la Reina/Spain.

Ms. Asunción García-Romero, the senior buyer at Schneider Electric, quickly released the initial samples. „Friedrich GmbH implemented our requirement in a perfect quality despite the demanding shape. This enables us to manufacture profitably with the progressive die in automatic mode. The eye for every small detail and the on-time processing of our order showed us that we made the right choice with Friedrich GmbH,“ said Ms. García-Romero at the end of the project.